On the coating, slitting, production, and die-cutting machines of the production process section, it is necessary to

Online detection and monitoring of surface defects on electrode plates (positive/negative).

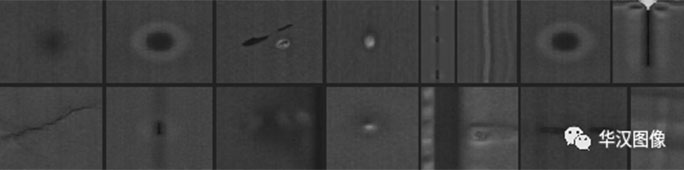

Testing requirements: scratches/streaks, metal leakage, bright spots, trailing edges

Decarbonization, bulging, black spots, bubbles, and tape splicing; Dimensional measurement; Marking, etc.

Camera selection: regular linear array camera/time-sharing exposure line scanning camera

Resolution: 4K/8K/16K

Scanning speed: 50-160m/min

Detection of electrode width: ≤ 800mm

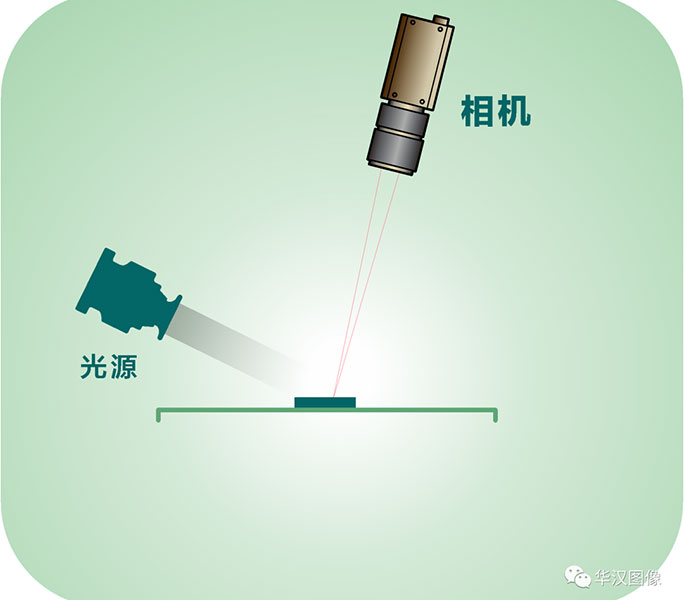

ordinary

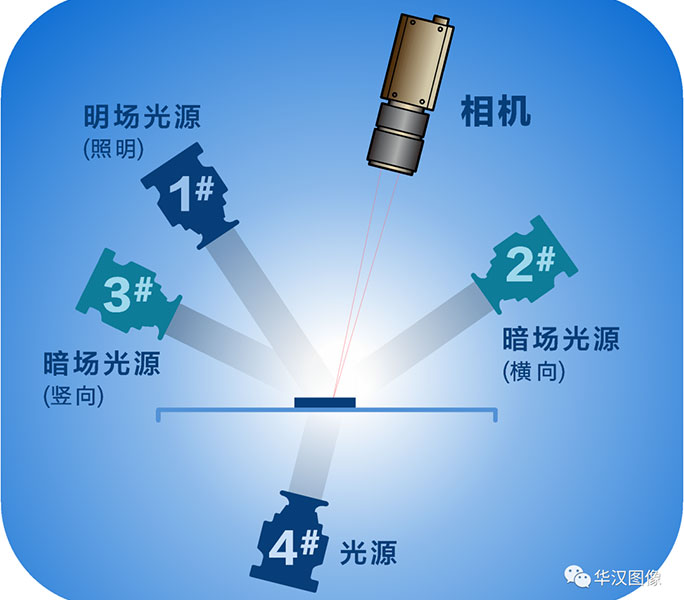

Time sharing exposure

Time division strobe technology can simultaneously detect bright/dark field/backlight defects, and can detect both horizontal and vertical scratches.

Speed: Meet the operating speed of 50-160m/min production.

Missing detection rate ≤ 0% (total number of missed detections/total number of detection electrodes); Misjudgment rate ≤ 0.1% (total number of misjudgments/total number of detection electrodes).

Can be used for detecting defects in polarizers such as coating machines, roller slitting machines, film making machines, and die-cutting machines.