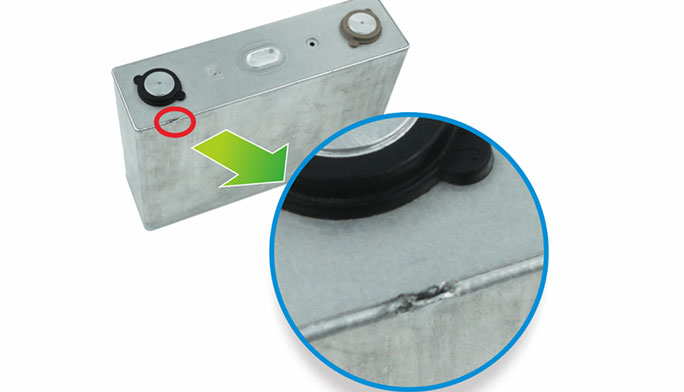

In the assembly process, the battery cells are sealed by laser welding after entering the shell. The quality of laser welding is affected by factors such as laser power, protective gas, and product surface material. Severe welding defects can lead to safety accidents such as liquid leakage and short circuits, while minor welding defects directly affect the appearance of the product.

Defect detection requirements: burst points, dents, pinholes, missed welds, broken welds, etc.

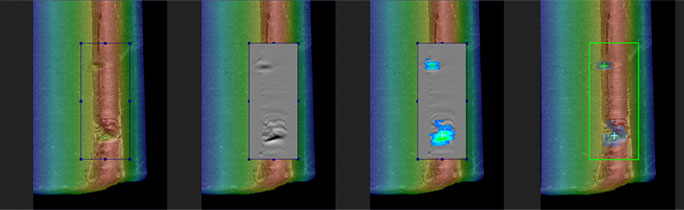

Camera model: 3D line scanning laser sensor

X-axis resolution: 12um

Z-axis accuracy: 1um

Scanning speed: 200mm/s

Detection time: 4.5s

Determine whether to add a rotating mechanism based on the product situation

Stable detection is achieved by combining the Huahan invention patent algorithm "surface defect extraction" with the "defect detection" algorithm.

It can stably detect burst points, dents, missed welds, broken welding defects, and pinhole defects greater than 0.2mm deep.

The overkill rate is less than 0.5%, and the missed kill rate is 0%.

Batch shipment.