As the largest field of machine vision application in China, 3C Electronics can see the presence of machine vision in various links of the electronic manufacturing industry chain, from imaging modules and USB connectors to devices such as phone frames and PC motherboards.

This includes application scenarios such as connector processing and assembly, screen alignment and fitting, and tablet scratch detection. In the entire consumer electronics industry chain mainly consisting of smartphones, computers, Bluetooth earphones, and smartwatches, Huahan Weiye provides five visual systems and visual intelligent detection equipment to assist the electronics manufacturing industry in creating unmanned and worry free factories, achieving cost reduction and efficiency improvement.

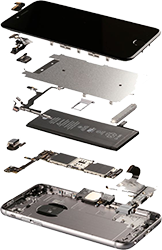

Measurement of SIM card slot size for mobile phones

Measurement of flatness/contour of mobile phone shielding cover

Type-C connector terminal flatness detection

Connector PIN pin alignment & height detection

Visual defect detection of shielding cover/hardware components

Appearance defect detection of connector terminals

Display foreign object detection in the tablet pad area

Display screen screw floating height & foreign object detection

Measurement of edge distance between display backplate & cover plate

3D guidance & re inspection of BG dispensing on the middle frame of mobile phones

Mobile phone frame flatness detection

3D guide for cutting the edge of the phone pouch battery skirt

Detection of appearance defects in mobile phone soft pack batteries

PCBA plugin post furnace welding quality inspection

PCBA/PCB plugin pin height measurement

TWS Bluetooth battery full size measurement

TWS Bluetooth earphone battery welding quality inspection

Quality inspection of dispensing on Type-C interface of mobile phones

Gap&Step measurement between the upper & lower covers of the power adapter

Appearance defect detection of mobile phone chargers