Defect sample generation

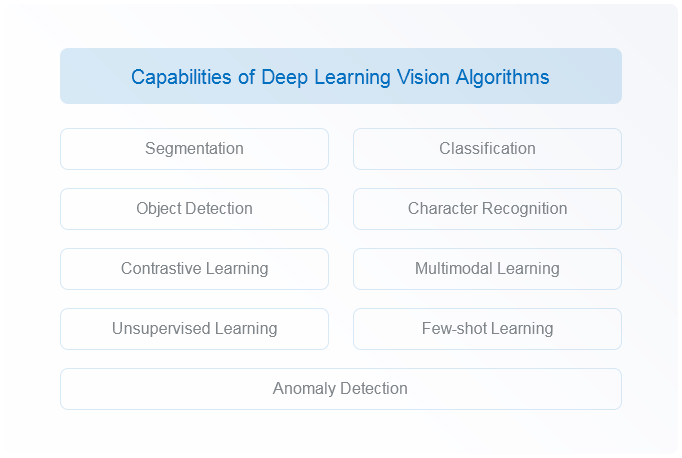

Data cleaning, important sample mining, and small sample learning techniques

Defect sample generation

Deep data analysis to assist intelligent decision-making

AI intelligent standards based on large models, binarization labeling, clustering labeling, and polygon labeling

Simplified labeling and lower professional requirements for personnel

Intelligent annotation upgrade, linear improvement in human efficiency

Inheritance learning and important sample mining

Noisy learning and super-resolution image block learning

Pre training weights

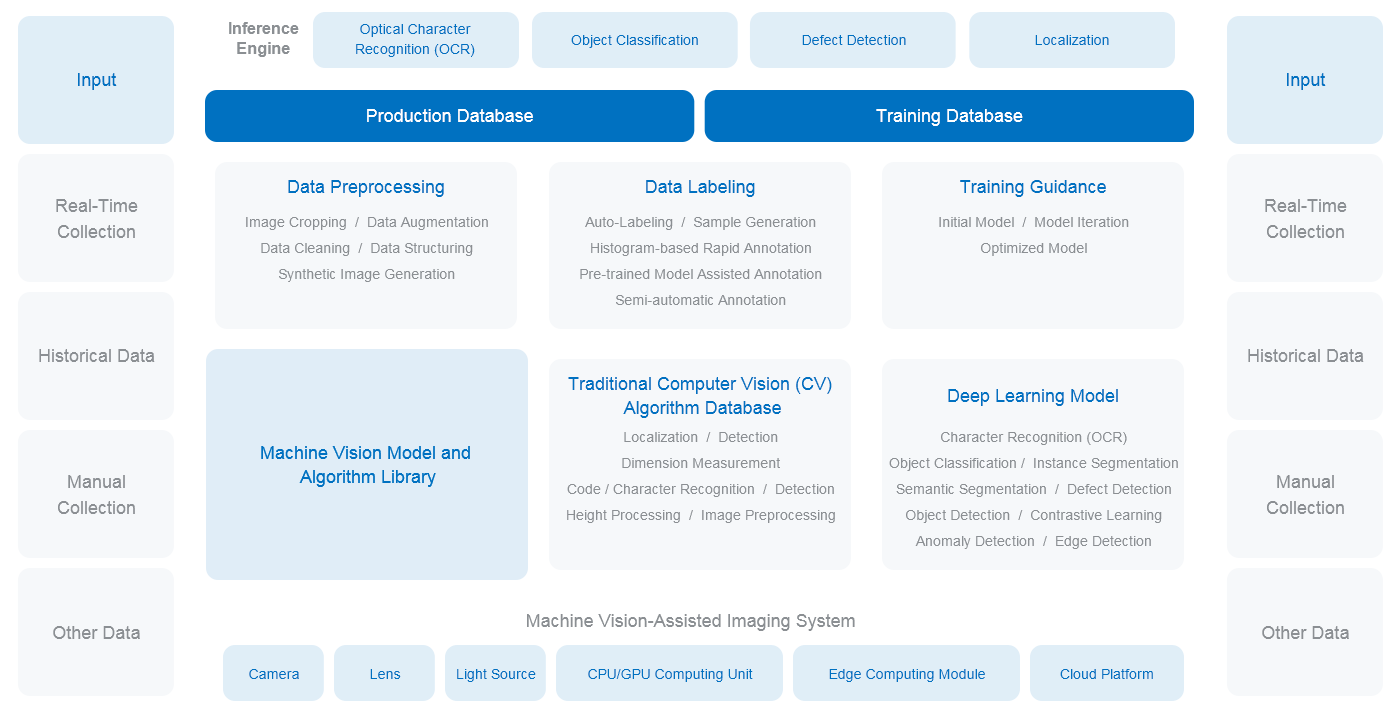

High degree of collaboration between cloud and end, breaking through the shackles of production lines

Multiple model compression methods

Sedimentation of high-precision algorithm models to achieve generalization and transfer of multi scenario models

TensorRT acceleration, performance improvement 3-5 times

SDK Ultimate Optimization, Flexible and Stable Development