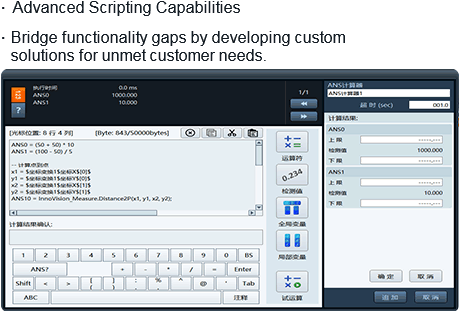

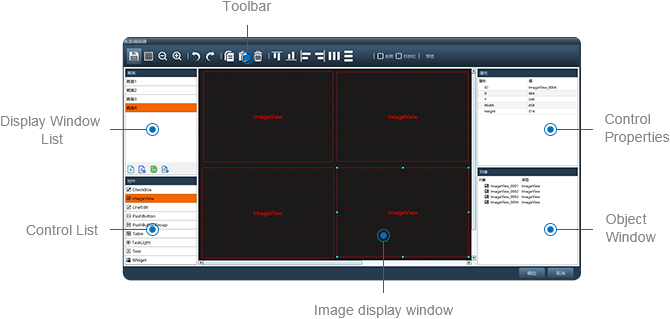

Innovision2D Standard intelligent vision system

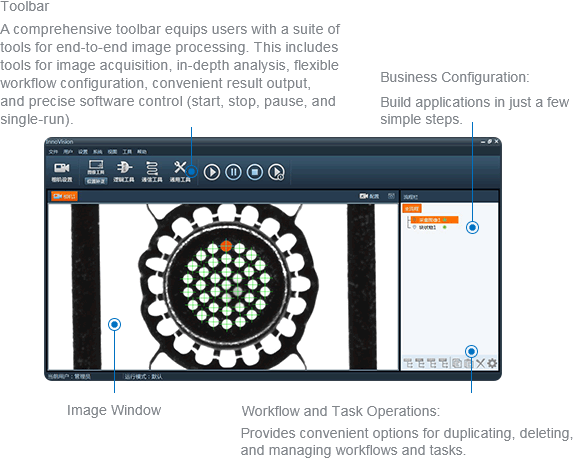

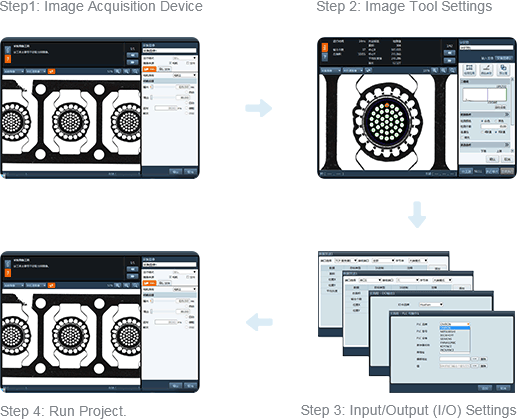

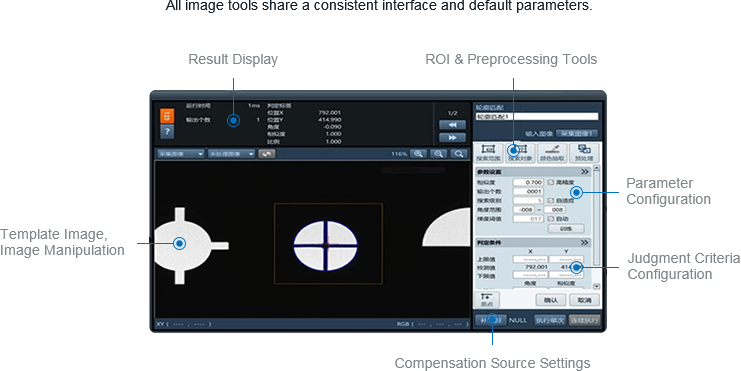

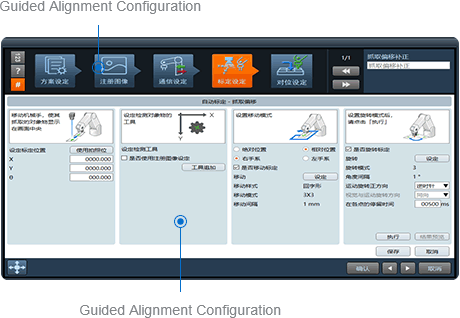

InnoVision 2D is a desktop universal vision inspection platform software, which can provide 2D image processing operators without code visual programming, support AI model import, can be applied to detection, measurement, alignment, recognition and other visual application scenarios, wizard interface design 3 steps to quickly open the ultimate visual experience.