With the rapid development of new energy vehicles in China, lithium-ion batteries for automobiles are entering the era of large-scale manufacturing. The cost, technology, and manufacturing level of lithium battery production determine the cost, driving range, and performance of new energy vehicles, which are the core components that hinder the development of new energy vehicles.

At present, lithium-ion power batteries are widely used in the new energy vehicle industry. The battery cell is the smallest unit of a battery system and the basic structure of a vehicle power battery. The manufacturing of battery cells requires a series of precise and complex processes such as pulping, coating, cold pressing, slitting, winding, baking, liquid injection, formation, and secondary liquid injection. Finally, the top cover plate is sealed with the battery cell shell through laser welding technology.

(Process flow diagram of power battery)

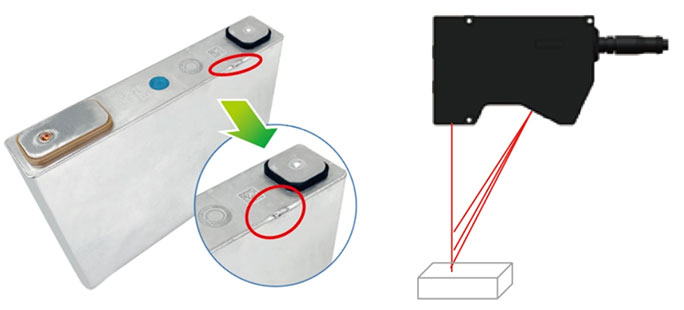

In the above process, the welding of the top cover plate of the battery cell is an important part of the sealing welding process, which is related to the safe and stable operation of the lithium battery. The related welding quality issues should not be underestimated, and are easily affected by factors such as laser power, protective gas, and product material. Defects such as explosion points, welding pits, holes, broken welds, missed welds, and flipping are prone to occur. Severe welding defects can cause safety accidents such as liquid leakage and short circuits.

(Structural diagram of the top cover plate of the battery cell)

Huahan Weiye solves the pain points and difficulties of top cover welding detection with its unique self-developed algorithm advantages. Through surface defect extraction technology, it efficiently analyzes and captures problems such as explosion points, welding pits, holes, broken welds, missed welds, and flipping. It can stably detect pinholes smaller than 0.1mm, avoid quality problems caused by electrolyte leakage, poor contact, or other welding defects. By using data sample adaptive expansion training technology, it shortens model training time and improves detection efficiency and accuracy through the role of algorithms.

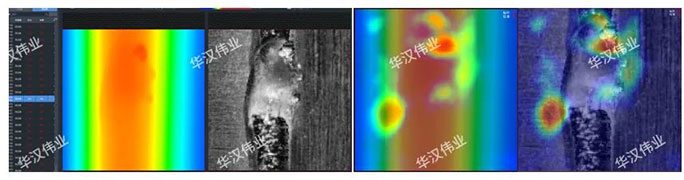

Huahan Weiye uses 3D+iSense AI detection technology for quality inspection, mainly using structured light technology for static shooting to avoid errors caused by mechanical movement. After processing the image, the defect position is accurately located based on the height information of the three-dimensional image. Based on point cloud defect detection, targeted defect detection algorithms are proposed according to the physical form of different types of defects. Based on deep learning, the obtained defect data is re evaluated.

Huahan Weiye deeply integrates 3D and AI technology, which can clearly distinguish defects such as burst points, weld pits, holes, broken welds, and missed welds. It has strong flexibility and high accuracy, and can achieve a scanning speed of 200mm/s and a detection time of 4.5 seconds. The on-site false detection rate is ≤ 1%, the missed detection rate is 0%, and the yield index of each implementation site reaches 99.5% or above. It is less affected by the external environment and truly achieves unmanned defect detection, reducing the subjective consciousness of visual inspection personnel and significantly reducing labor costs.

In the future, Huahan Weiye will continue to develop together with the lithium battery industry, further empowering machine vision capabilities in the lithium battery production process, helping lithium battery enterprises achieve precise quality control and project implementation, safeguarding the safe, efficient, and high-quality development of the new energy lithium battery industry, and supporting intelligent manufacturing of lithium batteries.