“Faced with the accelerated transformation of the automotive industry, the intelligent layout of automobiles with technological innovation as the core has become a new trend in industry development. The market share of new energy vehicles continues to rise, and the penetration rate continues to increase, driving the stable development of the industrial chain.”

The drive motor and its control system are one of the core components of new energy vehicles (battery, motor, electronic control), and their driving characteristics directly determine the main performance indicators of the vehicle's climbing, acceleration, maximum speed, etc.

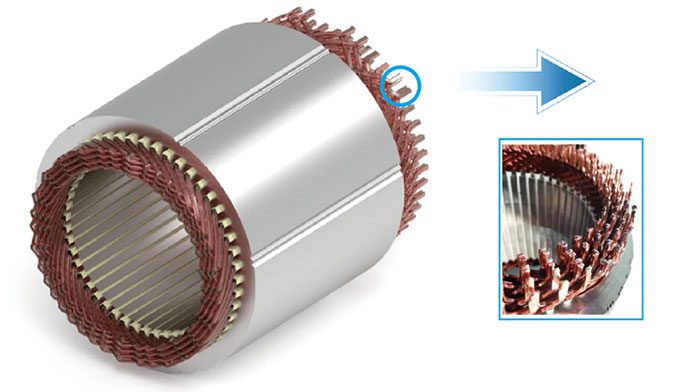

The motor is mainly composed of stator, rotor, and mechanical structure. In the production and manufacturing process, the stator has high requirements for structural strength and machining accuracy, and is an important standard for measuring the performance of electric motors. As an important component of electric motors, it is directly related to the assembly of the entire vehicle at the rear end.

The stator of the motor is mainly composed of silicon steel sheets stacked layer by layer, so it is necessary to connect the silicon steel sheets through welding. During the welding process, there may be defects such as missing welding at the tip, virtual welding, protruding and concave appearance at the end.

(Schematic diagram)

In response to the above situation, Huahan Weiye has customized a solution for detecting TIG welding points in motor stators.

1) Welding defects: Tig endpoint missed welding, virtual welding;

2) Appearance defects: The appearance endpoints are not full, smooth, and have inconsistent sizes;

3) Foreign objects: foreign objects at the endpoints, blackened paint, etc.

Huahan iSense AI Deep Learning Intelligent Detection System+3D Visual Detection System

Huahan Weiye uses 3D visual imaging to detect the location, number, and area of defects through positioning tools, block tools, and point-to-point distance tools, quickly completing the detection and accurately identifying subtle defects.

Through the empowerment of AI, the full chain flexible customization of data collection, analysis, and algorithm precipitation has been achieved, achieving a missed detection rate of 0, a misjudgment rate of ≤ 1%, and a position detection accuracy of ± 0.1mm.

(Presentation of renderings)

Huahan Weiye adopts a 2D/2.5D/3D vision+AI machine vision solution for the "three electric" system of new energy vehicles. Based on self-developed algorithms, it first locates the defect range and then performs detection and classification to improve recognition efficiency and achieve intelligent detection of actual production lines.

Simultaneously providing various advanced quality assurance technologies, we have shipped over 4000 sets of quality inspection systems and accumulated a large number of application cases.

For example, magnetic steel defects in motor rotor components; Steel sheet riveting point depth inspection, electronic control box component assembly defect inspection, engine cover plate sealant coating quality inspection, etc. ensure the reliability, efficiency, and safety of the inspection.

Huahan Weiye has mature experience in deploying production lines, helping enterprises reduce R&D technology investment costs, shorten project development cycles, and help improve production line quality and efficiency.

In the future, we will continue to iterate and polish products, improve product performance, continuously meet customer needs, and provide customers with the most competitive products and services in the market.