In May 2022, HANSWELL was invited to participate in the online exchange conference on "The Application of Machine Vision in the Lithium Battery and Photovoltaic Industry" hosted by the Machine Vision Alliance. Dong Liangliang, Director of the Solution Department of Huahan Weiye, delivered a keynote speech on "Key Technologies and Case Sharing of Visual Inspection for Lithium Battery Full Process".

In the field of machine vision, from industrial cameras to algorithmic platforms, machine vision products endow intelligent devices with "smart eyes", greatly improving work efficiency and accuracy, and reshaping enterprise productivity in the era of intelligent manufacturing transformation.

This speech mainly introduces the company's software and hardware products, as well as the application cases of the products in the entire process of the lithium battery industry, showcasing HANSWELL mature machine vision inspection technology and comprehensive production line deployment capabilities.

HANSWELL is positioned as a leader in industrial visual components and solutions, mainly providing a one-stop visual integrated platform of "algorithm+software+hardware+overall solutions",At present, there are implementation plans in the 3C electronics, new energy, semiconductor, logistics warehousing, and printing industries, especially in the 3C electronics and new energy industries, where there is very complete and mature project experience.

On the algorithm platform,HANSWELL self-developed MVDevelop algorithm platform, benchmarking against the world-class algorithm platform Halcon/VisionPRO, combined with customized framework software for the lithium battery industry, empowers core equipment manufacturers with application development capabilities, meets the visual defect detection application needs of the entire process of wound and stacked square shell batteries, customizes solutions to complex defect detection and defect classification difficulties, and continuously provides support for improving lithium battery production processes.

In the field of software platforms,The HyperShape 3D visual online inspection system with fully independent intellectual property rights can simultaneously handle 3D AI defect detection, 3D positioning guidance, and 3D& More than 90% of 3D application scenarios, such as 2D dimension measurement; We have integrated over 10 different brands and categories of 3D sensors, which can fully cover the detection accuracy requirements of 50nm to 5mm.

In terms of product layout,The company has a deep accumulation in 2D imaging, 3D imaging, AI detection, and motion control technology, and its product layout in the industry is very comprehensive. In terms of hardware products, Huahan Weiye covers linear array cameras, intelligent code readers, intelligent cameras, 3D cameras, etc., achieving product coverage of multiple processes for power batteries.

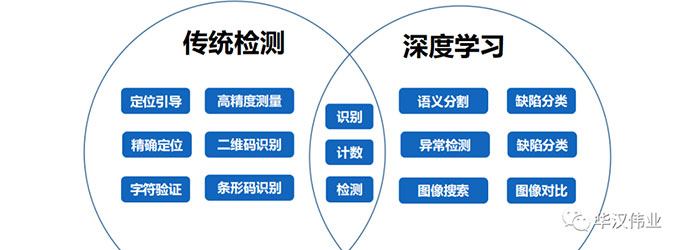

In the process of customizing solutions for the lithium battery industry, the detection requirements for complex defects and zero miss rates generated in different process stages of the lithium battery industry are addressed,HANSWELL strategy is to address complex detection defects through traditional detection algorithms combined with deep learning. Traditional algorithms handle defects with clear rules, leverage their respective advantages, and balance system performance, efficiency, and economy.

Looking towards the future, Huahan Weiye will actively embrace technological changes, deepen its cultivation in the field of machine vision, increase research and development investment, focus on talent cultivation, continue to make efforts in personalized customization, localized service capabilities, and supply chain optimization, expand application scenarios and fields, empower new industries, and assist customers in improving production capacity and efficiency.