In recent years, the development of artificial intelligence has entered deep waters. Among them, deep learning computer vision detection is an important direction in the field of artificial intelligence, and competition is particularly fierce. Although it has achieved great success in the research and development process, it still has obvious limitations.

Taking the practical application of AI in industry as an example, when encountering problems such as sample scarcity, high computing power requirements, long standard time, and long tail effects during project implementation, the universality and flexibility of deep learning are significantly limited, making it difficult to meet the needs of high computing power and low samples, which poses certain challenges for the breakthrough and improvement of AI.

Since the third wave of development in deep learning, artificial intelligence has developed more rapidly, intelligently, and with increasingly powerful functions. For example, in the field of image recognition, deep learning enables computers to recognize objects and scenes in images more accurately, efficiently, and even outperform the best manual detectors.

Nowadays, the application of AI in industry is very common, but its functions in practical applications mainly focus on basic recognition and detection, with severe homogenization. Most tool applications are also in the early stage.

With the increasing demand for customer business and innovative applications, more stringent requirements have been put forward for the efficiency and quality of AI reasoning and training. The hot competition of visual inspection enterprises has also shifted from the initial layout of AI to the creation of "new concepts", gradually iterating to let deep learning computer vision inspection technology step out of the ivory tower, allowing computers and automation equipment to truly understand images, endowing machines with the ability to "understand", and ensuring meaningful interaction with the real world.

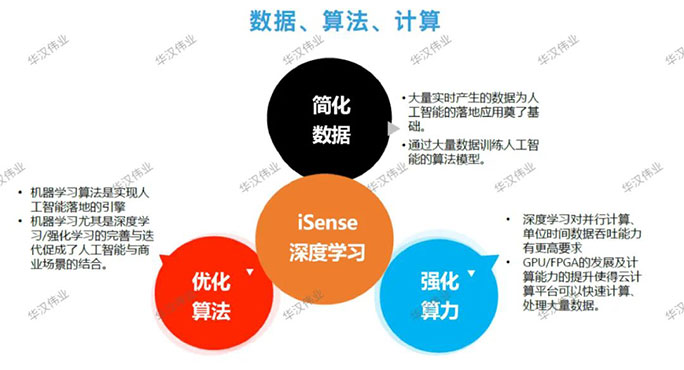

How to further promote the upgrading of AI deep learning image detection technology, the R&D personnel of Huahan Weiye have found new breakthroughs in data, computing power, and algorithms. Based on deep learning, image analysis aims to create an AI vision software that is both accurate, economical, and fast, solving the problem of traditional image processing relying on rule detection, improving machine self-learning ability, and quickly realizing the development of non-standard projects.

Generally speaking, deep learningstill has some inherent contradictions between data,computing power, and algorithms: the wider the width of data types, the higher the dynamic range and accuracy they can express, which means more storage space is needed and also poses challenges to computing power; At the algorithmic level, the efficiency and degree of optimization of algorithms also directly affect the computing power of computers./span>

Therefore, in China, Weiye is building iSense; In AI visual software, three key elements are needed to work together: simplifying data, enhancing computing power, and optimizing algorithms. In the process of tuning these three elements, algorithmic innovation is of utmost importance for iSense.

In the process of industrial quality inspection, traditional algorithms calculate data through custom rule functions. However, as the number of defects in the production process increases, manual labor cannot define all possibilities. Therefore, traditional visual inspection algorithms are suitable for identifying and detecting simple and regular defects; Deep learning can automatically extract the features of defect sample data through machine self-learning, achieving accurate discrimination of complex and irregular product defects. At the same time, by training defect sample data, the model can be customized and optimized. Therefore, compared to traditional algorithms, deep learning algorithms can be applied to complex detection scenarios, and big data learning can achieve high accuracy and low misjudgment rates.

HANSWELL iSense AI visual detection software enhances detection performance by integrating deep learning algorithms with traditional detection algorithms, while also reducing reliance on algorithms. It can quickly achieve the development of non-standard projects and meet the personalized development needs of customers.

ISense AI advanced image processing platform, using TensorRT (deep learning) acceleration technology and multiple model compression methods, achieves accurate, economical, and fast performance improvement of 3-5 times, achieving low precision and high efficiency!

In the process of model training, compared to most domestic visual inspection companies, the iSense detection platform not only supports 2D single image input, but also can achieve 2D multi image, 3D image, and 2D+3D image input, covering three major steps: preprocessing, segmentation positioning+template matching, classification and identification+intersection and disconnection. It effectively solves problems such as performance degradation caused by small defects, size, color difference, and rotation differences, and is at the forefront of the industry in computing power comparison testing.

At the same time, the iSense detection platform, based on AI technology, has achieved algorithmic platformization through the development of eight product characteristic tools, including multimodal learning, instance segmentation, 3D+2D segmentation, 3D+2D classification, rotating object detection, contrastive learning, automatic generation of defect samples, and unsupervised learning. It helps industrial production lines deploy quickly, and assists enterprises in improving product quality and manufacturing processes.

For the diverse application needs of industrial testing in multiple scenarios, a patented "multimodal learning" feature tool covers different encryption algorithms in 2D/3D/AI. According to project requirements, different functional modules can be flexibly combined, such as "2D+3D, 2D+AI, 3D+AI, 2D+3D+AI" and other combination modes. It can achieve "1 platform+N modes+X application scenarios=∞ solution", fully meeting the needs of users for more application projects and empowering multi industry applications.

The instance segmentation module not only predicts categories, but also identifies each different individual, detects the number of defects, and counts the area of each defect; Rotating object detection can effectively handle scenes with complex backgrounds or dense targets; The image generation technology based on heterogeneous feature exchange, also known as defect sample generation technology, can achieve data cleaning, important sample mining, and intelligent synthesis of defects, solving the problem of sample scarcity in the industry

In the era of AI, applications are king. How to evaluate whether a new technology can lead the future development direction? We need to see if it can fundamentally liberate and develop productivity, and in the AI+manufacturing industry, to judge whether a software can be accepted and recognized by the market, we need to see if it can solve the pain points and difficult problems of the industry in the most cost-effective way, truly helping manufacturing enterprises achieve "more fast, better and more cost-effective" quality inspection.

In response to the demand for small-scale and rapid production of quality inspection in the manufacturing industry, Huahan Weiye iSense testing software adheres to the original intention of becoming a "practical worker" in industrial intelligent testing, achieving the landing of "thinking", "doing", and "using" technology.

Taking practical application cases as an example: In the production process of lithium battery industry, the welding quality inspection of top cover welding is greatly affected by the welding technology level, environment, and production process, and requires extremely high requirements for the size, missed detection rate, and false detection rate of pinholes. This is a major pain point in the industry. iSense is based on the application of 2D+3D classification/segmentation patent technology, which can effectively identify pinhole sizes of 0.1mm, with a false judgment rate of ≤ 0.3%. The industry requires a false judgment rate of ≤ 1% for this project.

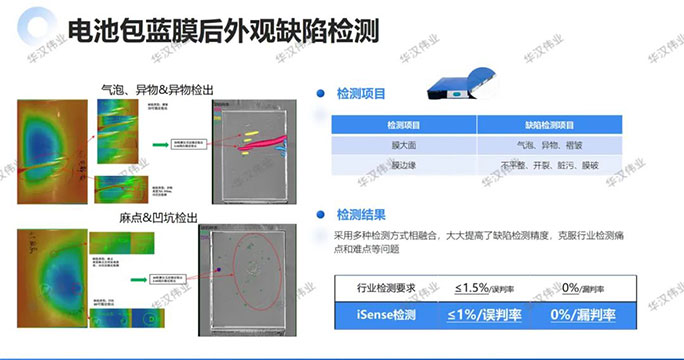

The main difficulties in detecting appearance defects of the blue film are:

1)The high reflectivity and low contrast optical properties of the material itself result in many defect features not being obvious (such as concave spots and deformations that are very flat, and the contrast of ordinary camera images is very low, making it difficult to identify defects, bubbles, and creases). Traditional algorithms have extremely high pass and miss rates;

2)There are many types of defects, such as bubbles, wrinkles, pressure marks, dirt, and membrane rupture, making it difficult to collect samples of these types of defects;

3)The production line has a fast pace and requires high algorithmic efficiency in software, so this project is also a key challenge that the industry needs to tackle.

The company continues to make efforts in this project. Based on the single model detection technology of multiple types of images with phase deflection, it overcomes the problem of high reflection and low contrast, adopts time-sharing stroboscopic detection scheme, and creates a cost-effective landing scheme. The rate of missed judgment is 0, and the rate of miscarriage of judgment is ≤ 1%, while the industry's requirement for miscarriage of judgment in this project is ≤ 1.5%; At the same time, this plan saved 30% of project implementation costs and has received continuous praise from customers.

“Intelligent manufacturing must have the same frequency of thinking as manufacturing enterprises, starting from practical difficulties, and extrapolating possible solutions. As a "practitioner" of industrial AI testing, Huahan Weiye always stands from the perspective of manufacturing enterprises, analyzing the pain and difficulty issues of AI industry implementation from various dimensions, extrapolating the functions that AI products need to upgrade and optimize, and continuously iterating solutions.

Through technological innovation, HANSWELL overcomes the barriers of deep learning detection technology, creates differentiated AI detection software, and implements its technical products in practice, expanding the boundaries of AI+applications. In the future, Huahan Weiye will continue to specialize in its own field, strengthen its large and complete functions and higher cost-effectiveness, and become an industrial AI detection expert.