With the rapid growth of new energy production capacity, soft pack lithium batteries, as a new generation of energy storage power sources, have superior performance and wide applications. However, the aluminum-plastic film shell material used is relatively soft and susceptible to damage, inevitably resulting in some defects that directly affect the consistency and safety of the battery, posing a serious threat to the safety performance of the battery, and may even cause electrolyte leakage inside the battery, leading to safety accidents such as fires. Therefore, the corresponding level of appearance inspection technology directly determines the quality of battery products.

Phase deflection, as a commonly used detection technique in the quality inspection of soft pack batteries, has also played an important role in machine vision inspection.

结Structured light is a system structure composed of a projection device and a camera. By using a projection device to project sine stripes, the sine stripes are projected onto the surface of the object through the projection device. The camera is used to capture the degree of curvature of the stripes modulated by the object, demodulate the bent stripes to obtain the phase, and then convert the phase into the full field curvature.

Figure 1 Projection Gray Code+Phase Shift Image

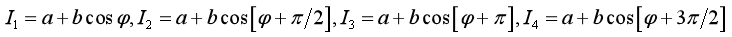

To adjust the phase, a common approach is to combine the phase image with the Gray code image. Assuming that the intensity of the projected stripe image is a standard sine distribution, the intensity distribution function is:

If the commonly used four step phase shift scheme is adopted, the projections are:

Therefore, the phase can be obtained as: image. After obtaining the phase, the absolute phase can be obtained based on the Gray code: image, where k is the period of the phase. After obtaining the phase, the phase height relationship can be obtained based on the calibration relationship, thereby obtaining the surface morphology of the object.

In addition, it is also possible to estimate the normal vector of the object surface using only the phase, and obtain gradient information in the X and Y directions of the surface based on the normal vector, which can be used for surface defect detection.

Phase deviation has a good detection effect on scenes with low contrast, high reflectivity, and certain concave convex changes.

The entire system consists of two line scanning cameras, which capture the upper and lower surfaces respectively. Each camera is equipped with a light source that can project sinusoidal stripes in the X and Y directions.

Figure 2 Hardware Structure Diagram

Figure 3 Shooting effect picture

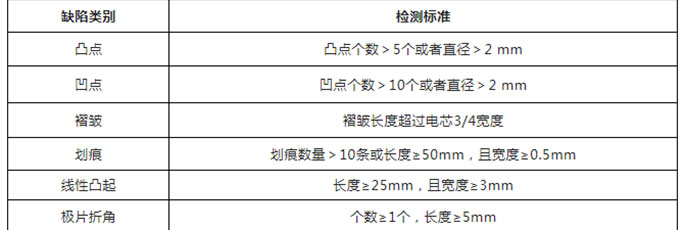

Mainly detecting 6 types of defects: protrusions, indentations, wrinkles, scratches, linear protrusions, and pole bending angles. The detection standards are shown in Table 1.

Table 1 Defect Detection Standards

This project adopts a combination of deep learning and traditional image processing to solve the problem. Traditional image processing utilizes Huahan Weiye's self-developed "defect tool" to determine and solve the defect quantity.

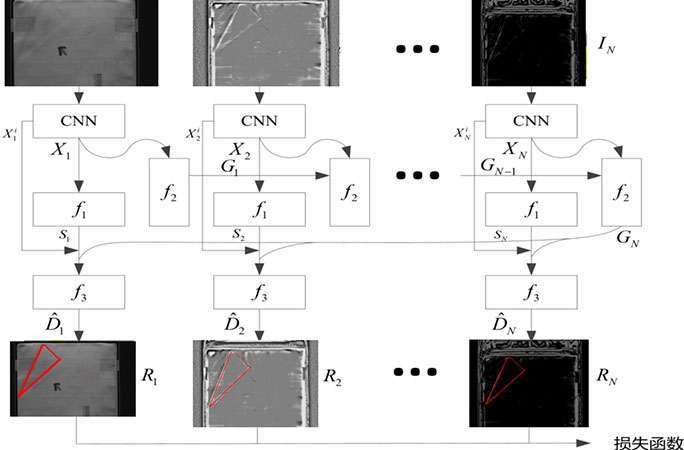

Deep learning adopts an image feature fusion scheme based on image streams for semantic segmentation. Input multiple images such as diffuse reflection, shape, and gloss ratio into the CNN convolutional neural network module for feature extraction, then input the features obtained from each image into the RNN network structure for feature fusion, and finally obtain defect detection results based on the fused features.

Based on the fusion of traditional methods and deep learning, the detection accuracy of soft pack batteries is greater than 98.5%, the kill rate is less than 2%, and the miss rate is less than 0.2%.

Figure 4 Schematic diagram of detection effect

In machine vision detection, phase deviation can generate 8 images that are suitable for the purpose through one shot, and can be further fused into multiple types of images through phase deviation. It can accurately extract the parts with height changes, making defects more clear. Huahan Weiye not only applies it to the appearance inspection of soft pack batteries, but also realizes batch application deployment in the entire process of production, battery cells, and module PACK in the lithium battery industry. It has been applied in hardware component appearance inspection in the 3C industry, automotive surface inspection in the automotive industry, glass appearance defect inspection, high reflection and low contrast, and other scenarios, and has received widespread praise from industry customers.

Currently, Huahan Weiye has a comprehensive product layout and comprehensive AOI solutions in 2D, 2.5D, 3D, AI, and line scanning. With comprehensive underlying algorithms and differentiated solution capabilities, Huahan Weiye has overcome the complex detection difficulties in complex application scenarios in industries such as lithium batteries, 3C, and semiconductors. In the future, Huahan Weiye will continue to deepen its cultivation in the machine vision industry, innovate technology applications, and assist intelligent manufacturing.