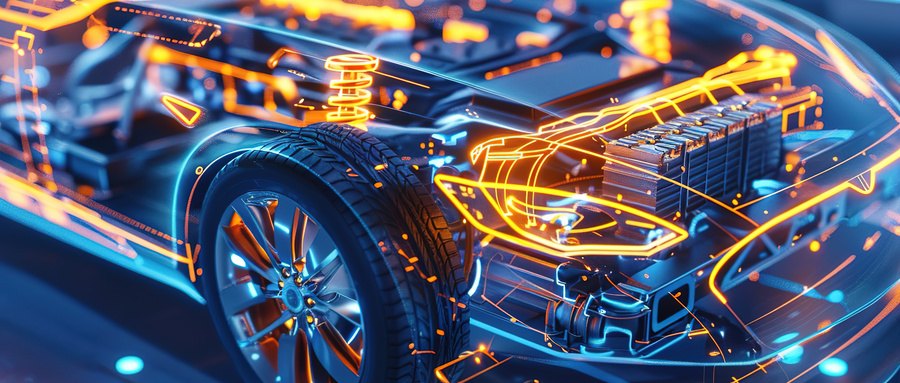

In the process of automobile manufacturing, the safety and matching degree of automotive components play a crucial role. Improper component combinations may lead to safety issues such as power loss, increased vibration, and increased noise. The manual quality inspection method is not only inefficient, but also easily influenced by personal abilities, leading to missed or false inspections, which cannot meet the modern manufacturing industry's demand for efficiency, accuracy, and reliability.

Therefore,under the trend of intelligent and lightweight development, the demand for machine vision in the automotive industry is expected to continue to increase.

With the complexity of the manufacturing process for new energy vehicles, there is a significant increase in the required precision components, which puts higher demands on the efficiency and accuracy of testing.

Huahan Weiye is driven by innovation, equipped with 3D+AI technology and machine vision to enter more application scenarios, achieving intelligent and flexible production of components, and helping end customers significantly improve production efficiency and quality standards on the production line.

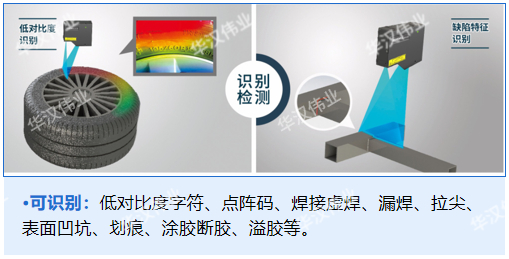

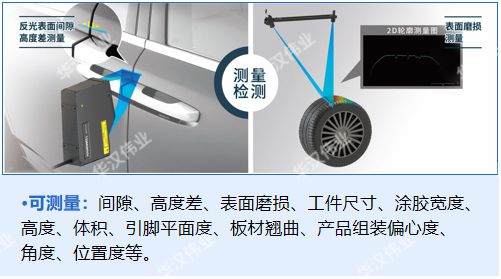

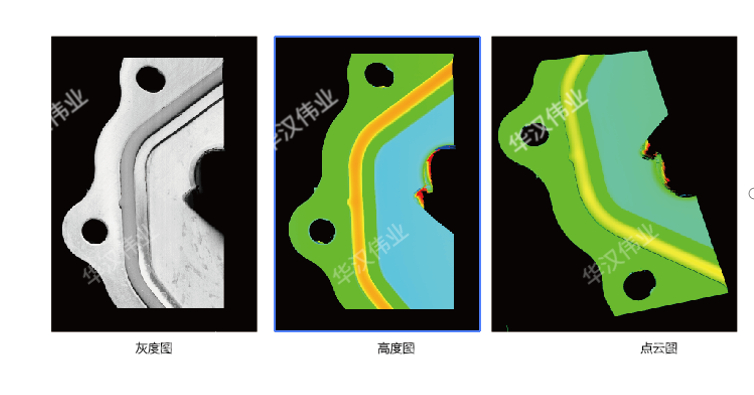

The Huahan Weiye HyperShape 3D visual online inspection system adopts a 3D imaging method based on 3D vision, and uses irregular adhesive path grabbing tools and continuous contour tools to detect the quality of adhesive coating,It can detect various types of colloids, and can achieve accurate recognition and detection even in situations where the coating thickness/height is abnormal, the adhesive track is close to the background color, and low contrast, improving product yield and fast calculation speed,Realize a missed detection rate of 0 and a misjudgment rate of ≤ 0.5%.

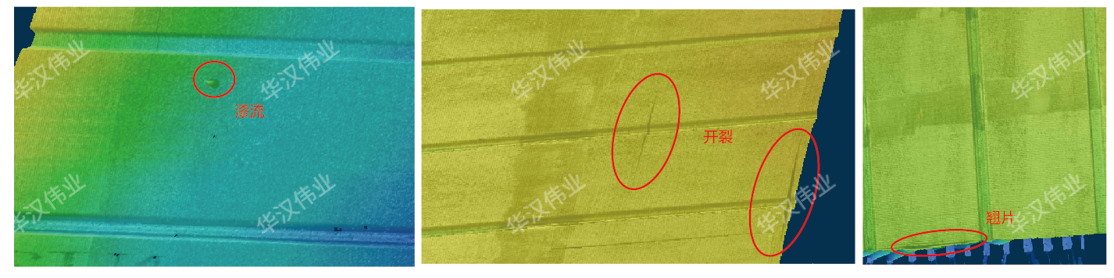

Huahan Weiye 3D+AI visual inspection technology uses defect tools to accurately capture the location of small paint flows. At the same time, continuous contour analysis is used to effectively detect the situation of end face warping, stably identify gaps, and output the specific width of gaps, with a missed detection rate of 0, meeting the project detection requirements.

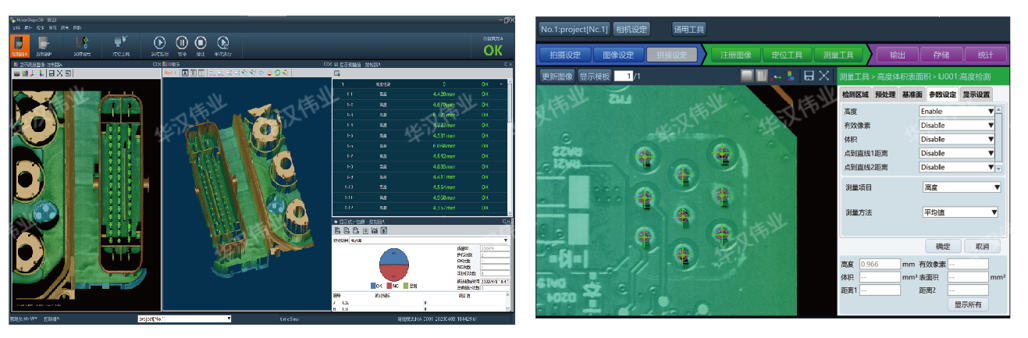

Automotive parts PCB boards usually contain a large number of PIN pins, which are numerous, dense, have a small surface area, and are made of metal reflective materials,Huahan Weiye introduces 3D vision technology and image processing algorithms to achieve non-contact and high-precision PIN pin height detection,Being able to quickly and accurately obtain the three-dimensional coordinate information of the PIN pin, ensuring perfect imaging, achieving a false alarm rate of 0 and a false alarm rate of ≤ 1%, helps to ensure the electrical connection performance and mechanical stability of automotive accessories.

Huahan Weiye applies 3D+AI visual technology to size measurement and appearance defect detection of automotive components, combined with the perfect combination of industrial cameras and industrial lenses, which brings high stability and high usability, further improving the efficiency and quality of the entire production process.

At present, high-quality, efficient, and intelligent solutions have been implemented on many project sites, helping users shorten product testing time, improve the accuracy of testing results, and meet the industrial production needs of modern automobiles.

In the future, Huahan Weiye will continue to innovate technological versions, expand product boundaries, work together with partners to explore new levels of perception, and continuously promote the upgrading of industry flexibility and intelligence.