In the process flow of module pack section, after module assembly, it is necessary to conduct overall flatness testing on the bottom surface of all battery cells, as well as coplanarity testing on the four fixed angle support end plates, to prevent subsequent installation defects.

Testing requirements: flatness: tolerance control of 0~0.3mm;

End plate coplanarity: tolerance control of 0~0.2mm.

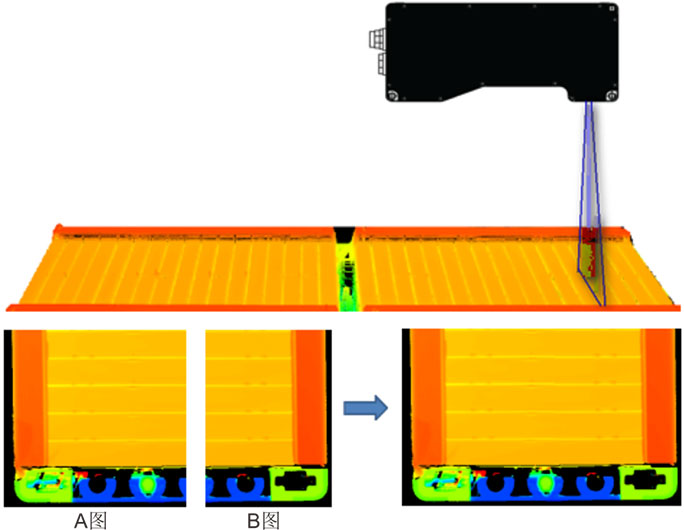

Camera model: 3D line scanning laser sensor.

Z-axis accuracy: 20um.

Scanning speed: 160mm/s& nbsp; Detection time: 3.5s.

Different from the width and accuracy requirements of the module product, a single scan scheme with a large field of view and a multiple scan splicing scheme with a small field of view can be selected.

Detection method: Use the least squares method to measure the flatness of the module bottom surface and the coplanarity of the end plate.

Dynamic repetition accuracy: 0.02mm.

Measurement accuracy: 0.03mm.