In recent years, with the rapid rise and development of technologies such as image processing, optical imaging, sensors, and processors, machine vision has been widely used in people's production and life. From industrial production to security and transportation, it is driving the rapid transformation of many industries, including manufacturing.

Under the global demand for Industry 4.0 and automation, how to achieve precision, efficiency, and optimal cost has become the key indicator that production enterprises are most concerned about.

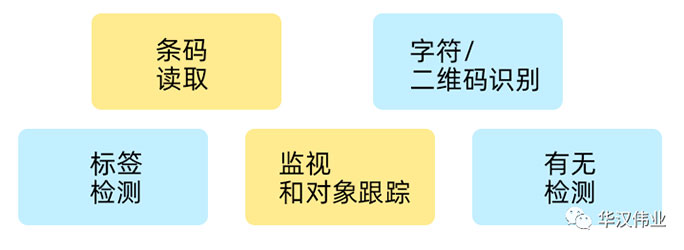

The InnoVision 2D standard vision system, independently developed by Huahan Weiye based on multi-core processors and GPU architecture, is a universal intelligent vision system that integrates software and hardware. It mainly uses two-dimensional image processing technology and integrates more than 150 image processing tools such as preprocessing, positioning, measurement, and recognition. It integrates rich image processing tools and can quickly and stably make accurate detection and judgment of single plane defects in products. It is widely used in industrial image 2D positioning/alignment/detection/measurement/code reading/character recognition and verification scenarios.

Built in the MVdevelop underlying algorithm independently developed by Huahan Weiye, it supports 12 tool groups and more than 150 image tools, which can better adapt to the needs of different application scenarios.

The self-developed underlying algorithm has been compared and tested with the world-class algorithm library MVTec's Halcon. The accuracy error of the algorithm is less than 10-4, and the running efficiency is equivalent to it. It has completed optimization of instruction sets SSE and AVX, parallel algorithms, and is currently at the leading and first tier level in China. The Huahan Weiye algorithm development package can achieve domestic substitution and has the ability to develop and solve industry problems at the underlying level, enhancing the basic development ability in the field of vision in China.

Integrated "intelligent learning" defect detection module, capable of handling complex scene defect detection; In response to the pain points of small defect samples and difficult acquisition in defect detection applications, a combination of 2D+AI deep learning is used to support fast online training and defect detection through a small number of OK and NG samples, which can greatly shorten the deployment cycle of the project.

InnoVision 2D supports configuration functions and can customize the production interface; By using this function, you can set to display only production related parameters and charts; Or change the style and color scheme to match the production environment standards. It can also cope with harsh detection environments, with high detection accuracy and fast speed.

Standardization of alignment application scenarios, 5-step guidance to complete all alignment applications; Extract 13 alignment scenarios, standardize configuration processes, and guide alignment settings. The drag and drop interface and zero code configuration greatly reduce the learning cost and threshold for operators, and lower the requirements for on-site personnel.

Background: In the production process of lithium batteries, after hot pressing, the lithium battery cells need to be paired with positive and negative electrode ears using a matching machine. In order to meet the process requirements and prevent defective products from flowing into the next process, causing unnecessary losses, the center distance/edge distance of the electrode ears is measured.

Plan: Huahan InnoVision 2D detection software, using linear tools to locate the upper edge of the top cover for initial positioning, fitting the bottom edge of the top cover and the upper edge of the film, measuring the distance from line to line, visual detection accuracy ≤ ± 0.1mm, missed kill rate=0%, pass kill rate<0.5%; Positioning/detection accuracy: ± 0.1mm, detection time < 0.5S, high accuracy, fast calculation speed, and can be shipped in batches.

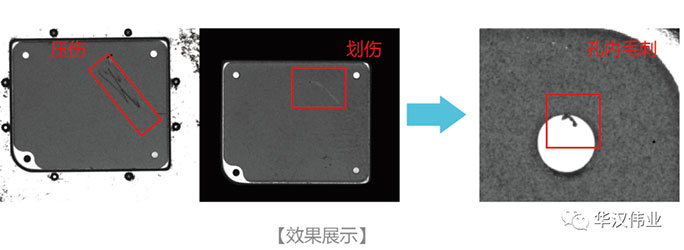

Background: In the 3C electronic manufacturing industry, the shielding cover above the mobile phone motherboard chip and electronic components is very important for the product. It can shield static electricity, prevent battery interference, and provide protection for electronic components. Therefore, it is necessary to conduct appearance defect detection on the shielding cover/hardware components.

Plan: A combination of Huahan 2D-AI, 2D for initial sample detection, and AI for online sample training and defect detection. A professional customized solution with high accuracy, detection time cycle ≤ 0.7s, can be shipped in bulk, saving a lot of manpower and time costs.

The 2D detection system, as an important software detection system of Huahan, not only includes traditional templates such as positioning, recognition, detection, and measurement, but also integrates image preprocessing and robot vision/guidance alignment functions.

Huahan Weiye has currently cooperated with multiple enterprises, using 2D software, 3D software, and AIDI Suite deep learning software and hardware integrated solutions to help enterprises upgrade their production line ecology, solve industry technical problems, efficiently empower industrial production, improve production efficiency, and build a sustainable, efficient, and open ecological cooperation circle.