As a national strategy for energy conservation and emission reduction, new energy vehicles are not only used for passenger cars, but also for various types of engineering vehicles. Therefore, major automakers have launched new energy vehicles one after another. As a new energy vehicle, power batteries are an indispensable and important component.

As a new generation of energy storage power supply, soft pack lithium batteries have superior performance and wide applications, and their production capacity is rapidly increasing. The aluminum-plastic film shell material used is relatively soft and vulnerable to damage. During the production process, some appearance defects are prone to occur, and some larger defects can pose a serious threat to the safety of the battery, which may cause electrolyte leakage inside the battery, and even lead to safety accidents such as fires. Therefore, the corresponding level of appearance inspection technology directly determines the quality of battery products.

As a provider of industrial visual components and solutions, Huahan Weiye addresses the difficulties in the inspection process by using dynamic high pixel industrial cameras and high-definition industrial lenses placed in multiple workstations, equipped with lighting systems for multi angle illumination, and cooperating with independently developed visual software systems to conduct comprehensive defect detection on soft pack batteries and automatically sort out products with non-conforming appearance.

In the process of detecting appearance defects of soft pack power batteries, there are challenges such as inconsistent battery colors, possible reflection of silver aluminum-plastic film, severe light absorption on black surfaces, and insufficient defect samples.

(Original image display)

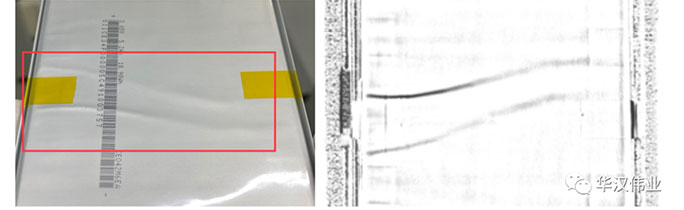

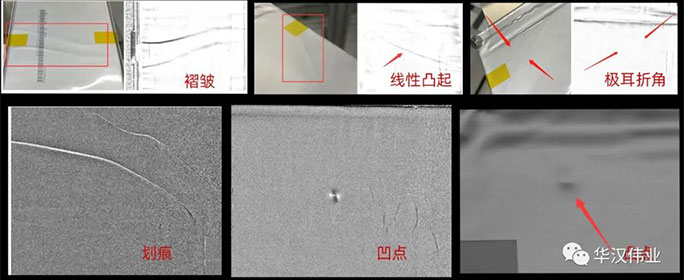

Foreign objects, scratches, wrinkles, poor pole ear, corrosion, dents, protrusions, pole ear folding angles, linear protrusions, and poor coding on the surface of the soft pack battery.

(Wrinkle NG judgment standard: A length greater than 60mm is considered NG)

Software: Huahan AIDI Suite Deep Learning Intelligent Detection System

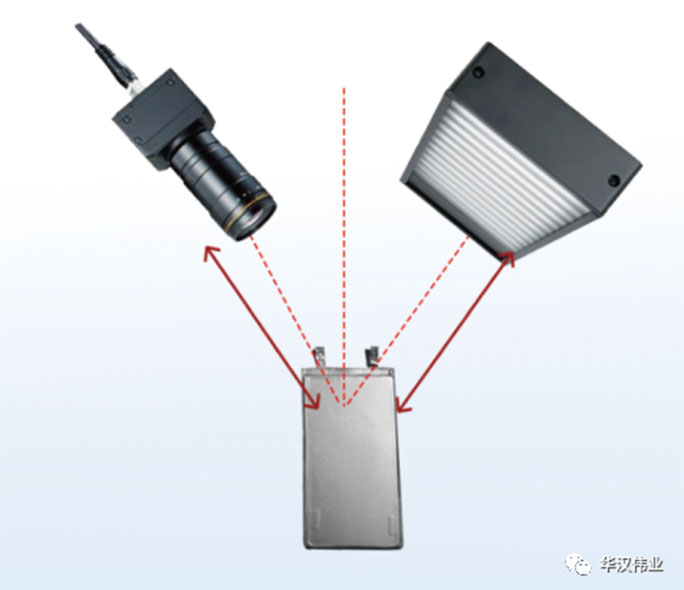

Hardware: 2.5D linear array camera+2.5D dedicated LED light source

(Lighting diagram)

1) A professional customized solution that can achieve stable detection and visualization simultaneously. Through one shot, multiple images that meet the purpose can be generated. 2.5D images can also extract highly variable parts, ensuring stable recognition, simple operation, and high efficiency.

2) The pixel segmentation module in the deep learning module can identify the location, number, and area of defects, with a missed detection rate of 0% and a false detection rate of ≤ 0.1%.

(Presentation of renderings)

The testing of power batteries is directly related to the performance and safety of new energy vehicles. The flexible customized solution of Huahan Weiye can effectively identify the appearance defects of workpieces, solve the problems of low efficiency and high missed detection rate of manual testing methods in the industry, greatly improve production efficiency, better control production quality, and save a lot of testing labor and labor costs; At the same time, it also improves the safety of soft pack batteries, avoids the circulation of defective products in the market, causes unnecessary after-sales problems, and affects brand reputation.

Moreover, the company has a self-developed underlying algorithm platform that can achieve optimization effects from the lowest level algorithms according to the actual needs of the project, meeting the requirements of project speed and accuracy. A machine vision system solution that integrates 2D/3D/AI in all aspects, achieving functions such as visual guidance, QR code recognition, character recognition, barcode recognition, product positioning, defect detection and classification, and multi image coordination processing for workpieces.

The software system is easy to operate and can be mastered by ordinary employees with just one training session; Short deployment and launch cycle, able to complete debugging as soon as possible; The company currently has a delivery team of over 100 people and practical experience in deploying multiple projects, which can meet demanding project time requirements. To ensure product stability and reliability, we can provide 7 * 24-hour after-sales service.