In recent years, with the rise and growth of the Chinese battery market, the phenomenon of independent research and development or leveraging research and development by car companies has become increasingly common. As the core component of new energy vehicles, power batteries not only account for nearly 40% of the total cost, but also directly determine the vehicle's range and user experience.

Nowadays, the power battery industry is sprinting towards the TWh era, and high-quality and efficient production requirements are driving the iteration and upgrading of new processes and equipment. Machine vision, as one of the key technologies in the production process of new energy power batteries, is a crucial link in the transformation and upgrading of the lithium battery industry to intelligent manufacturing.

At a critical moment when industrial enterprises are upgrading towards factory automation, industrial intelligence, and smart factory transformation, Huahan Weiye understands the core demands of relevant enterprises and is committed to working with numerous manufacturing colleagues to achieve the transformation of "cost reduction and efficiency increase" and "quality improvement" in intelligent manufacturing, reshaping enterprise productivity in the face of intelligent manufacturing transformation.

In the field of machine vision, Huahan Weiye focuses on "machine vision algorithms" as its core, focusing on machine vision, motion control, and AI detection technology. Combined with customized framework software for the lithium battery industry, it empowers core equipment manufacturers with application development capabilities to meet the visual defect detection application needs of extreme segments, battery segments, module segments, pack segments, and other process segments. It customizes solutions to complex defect detection and defect classification difficulties, continuously providing support for improving lithium battery production processes, endowing intelligent devices with "smart eyes", and significantly improving work efficiency and accuracy.

In the production process of power batteries, each link is interconnected, so it is necessary to firmly control the production quality of each process segment.

In response to the complex defects and zero leakage requirements in the lithium battery industry, HANSWELL provides industrial visual components and overall solutions for various production enterprises with a pragmatic service spirit, and has a good reputation in the industry.

In the field of software development, HANSWELL self-developed InnoVision 2D standard vision system can provide visual guidance, surface quality inspection, QR code recognition, character recognition, barcode recognition, and more for workpieces.

【2D software schematic diagram】

HyperShape3D The detection software system utilizes 3D images and point cloud data, and adopts technologies such as surface reconstruction, point cloud registration, point cloud stitching, and five axis linkage spatial interpolation to complete scene automation such as shape and position tolerance measurement, defect analysis, and welding guidance.

【3D software diagram】

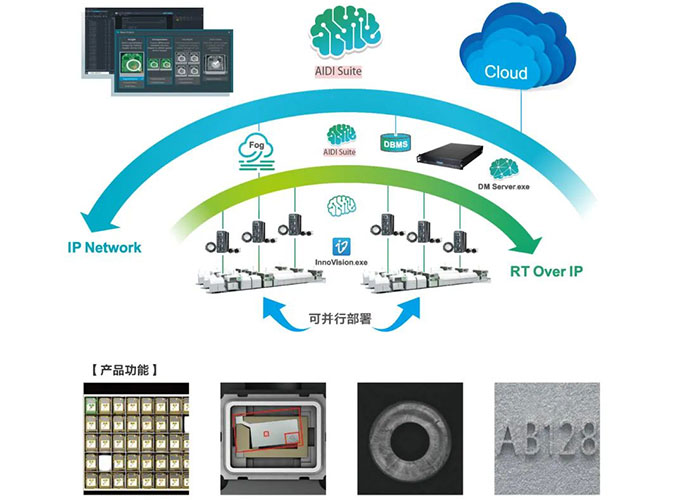

AIDI Suite Deep learning systems can achieve product positioning, defect detection and classification, and coordinated processing of multiple image streams, providing industrial vision AI application capabilities that reduce costs, increase efficiency, and improve quality for industrial customers.

【Schematic diagram of AIDI Suit software】

In terms of hardware products, HANSWELL mainly includes controllers, acquisition cards, cameras, lenses, light sources, DIO modules, 3D sensors, code readers, smart cameras, etc., which can achieve product coverage of multiple processes for power batteries.

HANSWELL customizes flexible product solutions according to the needs of different customers, quickly building software systems and hardware equipment suitable for production needs, meeting the full range of applications of lithium batteries in the front, middle, and rear stages, and comprehensively assisting in the intelligent manufacturing and upgrading of lithium batteries.

At present, industrial automation and intelligence have become the trend. Huahan Weiye adheres to the principle of customer centeredness, contributor centeredness, and long-term hard work, always focusing on innovation in technology, products, and solutions in the "intelligent manufacturing industry" to solve problems for customers.

Looking towards the future, Huahan Weiye will deeply cultivate the lithium battery industry, continue to prioritize product research and innovation, personalized customized solutions, and localized service capabilities, assist customers in improving production capacity and efficiency, and help enterprises move towards the Industry 4.0 era as soon as possible.