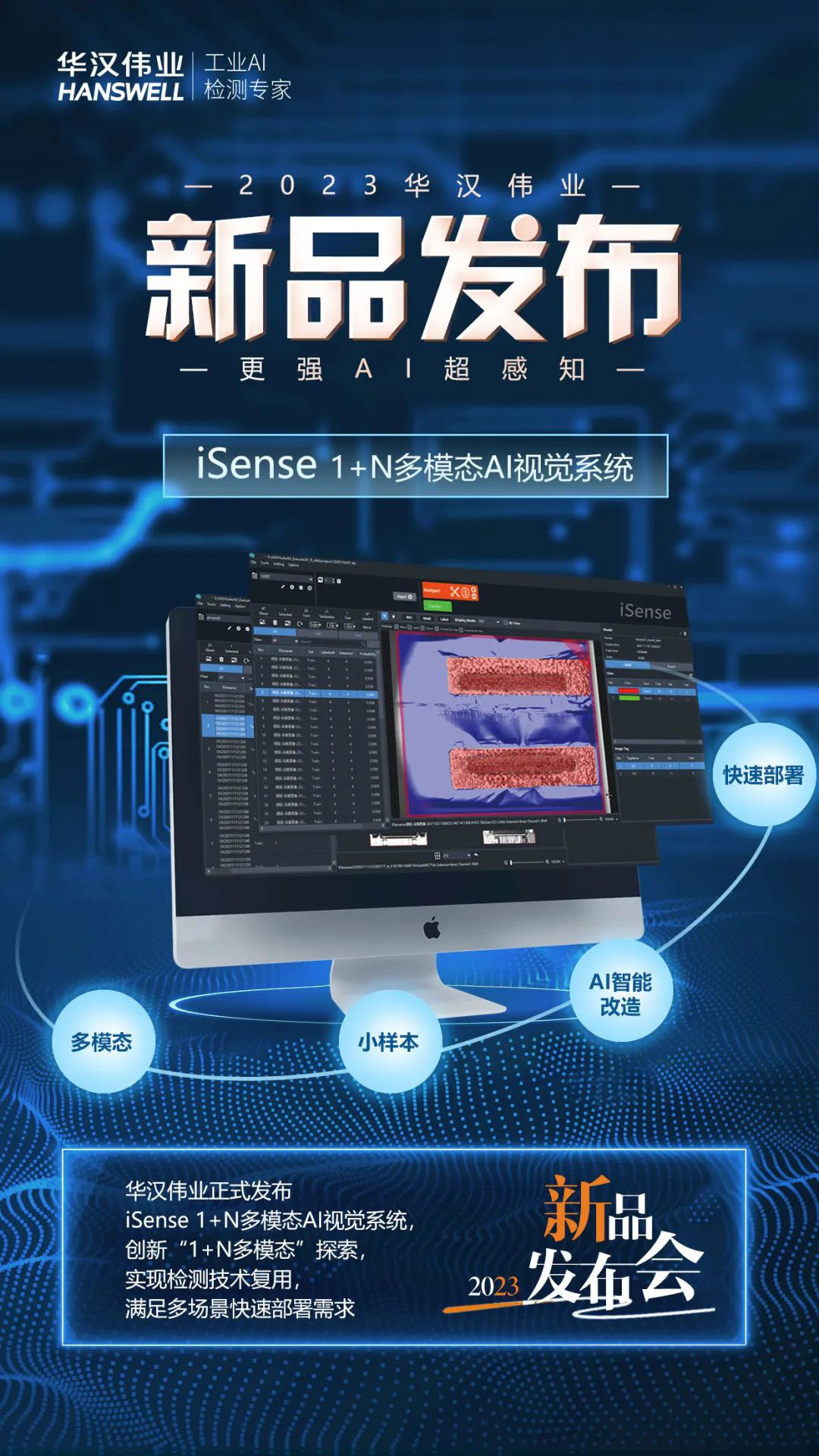

The ISense AI visual inspection platform features the highlight of "1 iSense platform+N modes+adaptation to X application scenarios"; Create N modes, including: 2D+AI, 2.5+AI, 3D+AI, 2D+2.5D+3D+AI... and other N mode combinations.

By highly integrating traditional algorithms with AI algorithms, it has been widely applied in over 1000 segmented industry application scenarios. Faced with rapid production and batch compatibility in multiple production lines and scenarios, it has deployed over 2000 visual systems and quickly adapted to the transformation and upgrading of enterprise production lines.

The iSense 2.0 visual system newly developed by Huahan Weiye is based on the characteristics of deep learning, meeting the needs of small sample and rapid deployment in production lines. It supports various adaptive learning modes such as continuous learning, transfer learning, small sample learning, and noisy learning.

Automatic defect sample generation meets the lower sample dependency of the production line, greatly enhancing sample richness. The production line quickly deploys and changes types, further shortening the integration and deployment time of visual projects, and empowering industrial quality inspection and upgrading.

The new generation iSense AI detection system is a new upgrade for the underlying algorithm, with a deep customized imaging system for real-time control. It adjusts the details of the entire process from the environment, equipment, and product ends, saves training time through one click cross regional transfer learning, and has multiple data enhancement functions to meet the needs of different scene data and transfer application capabilities.

The most direct value brought by iSense: empowering production through quality inspection, increasing production line response speed by more than 2 times, improving defect detection efficiency by more than 10 times, truly achieving the generalization and migration of single scene to multi scene models, and efficiently empowering intelligent manufacturing.

The iSense AI Vision 2.0 detection system, in addition to achieving multimodal configuration and rapid migration from single scene to multiple scenes, has also undergone iterative upgrades from user needs to the delivery end, and the client user deployment and delivery practice process has been optimized and deployed in batches.

From hardware integration to business delivery implementation management, all adopt process management and control, deeply ensuring 100% project delivery and comprehensive after-sales service from demand to implementation on the production line, ensuring worry free production.

In the era of machine vision 2.0, it is not only an era of ease of use and mass production, but also an era of moving from industrial manufacturing to "quality" manufacturing. It requires a new generation of vision that is "more flexible, faster to deploy, and more adaptable" to meet the upgrading of manufacturing towards "quality" manufacturing.

The iSense AI multimodal 2.0 visual system empowers the manufacturing of the future, starting from visual detection and dimensionality enhancement.

ISense's next-generation AI detection software,

On May 16th,

At the 6th International Intelligent Manufacturing Exhibition in 2023,

Official debut!

On site, you can experience the product from zero distance,

Coming soon!